Sucker Rod Pump (SRP) – Product Range

Reliable, field-proven SRP units built to API 11E standards for diverse lifting capacities and industrial applications. Available in five standard models with precision-balanced beam design, rugged construction, and long service life.

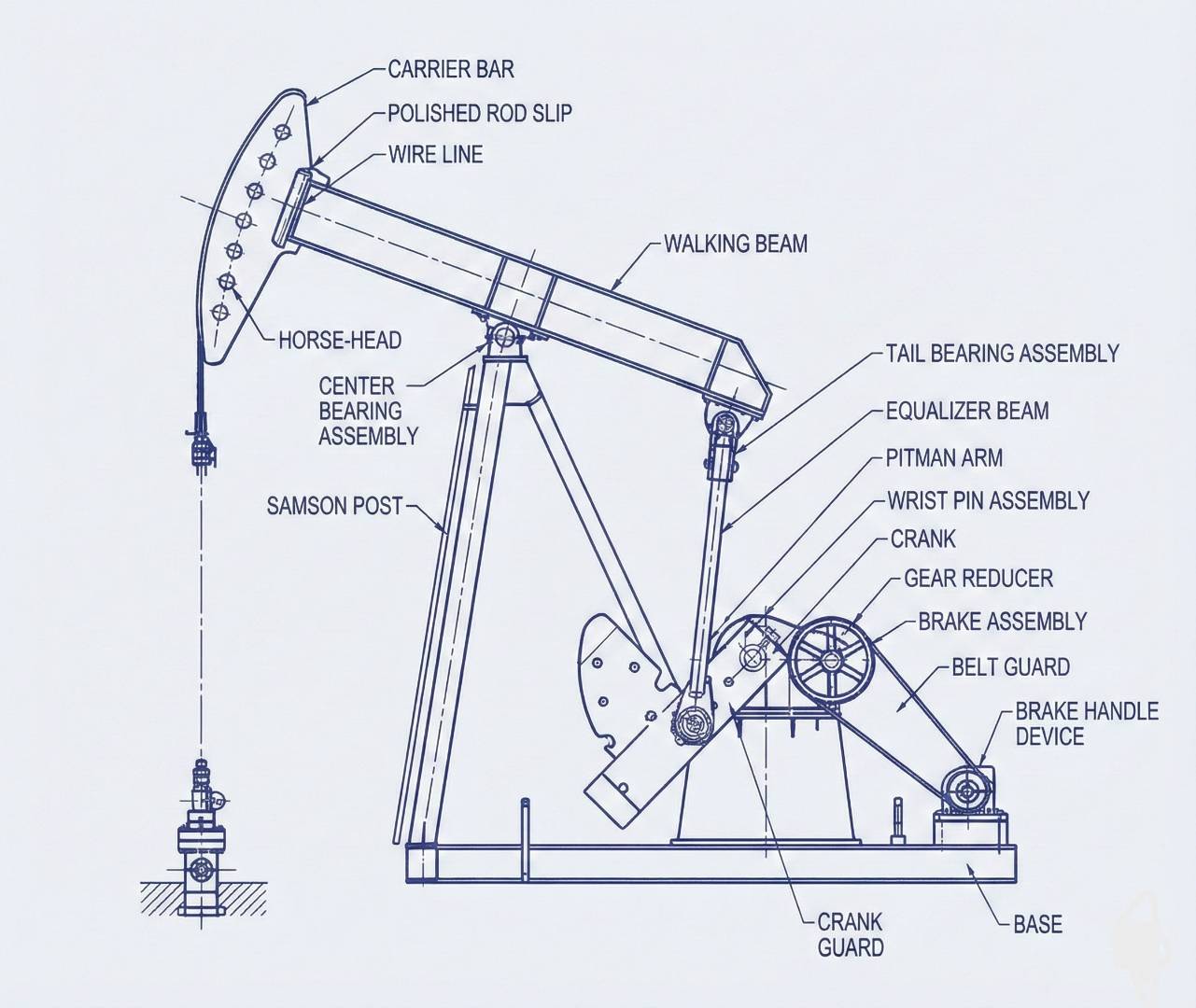

*Schematic representation of a standard Sucker Rod Pump unit showing major components.*

| Sr. No. | Component Name | Function / Description |

|---|---|---|

| 1 | Prime Mover (Motor) | Provides rotational energy to drive the gearbox. |

| 2 | Gearbox | Reduces speed and increases torque for crank operation. |

| 3 | Crank & Counterbalance Assembly | Converts rotary motion into reciprocating motion and balances dynamic load. |

| 4 | Walking Beam | Acts as a lever transmitting motion from crank to polished rod. |

| 5 | Pitman Arm / Connecting Link | Connects crank assembly to walking beam end. |

| 6 | Bearing Housing / Samson Post | Supports and allows pivot motion of the walking beam. |

| 7 | Horse Head | Curved end of the beam connecting to the polished rod clamp. |

| 8 | Polished Rod | Connects surface unit to the subsurface pump rod string. |

| 9 | Stuffing Box | Seals the wellhead around the moving polished rod to prevent fluid leakage. |

| 10 | Baseplate / Skid Frame | Structural base supporting the entire pumping unit. |

Detailed technical specifications are available as downloadable PDF datasheets.

| Pumping Unit Designation As per API 11E | Reducer Rating in.-lb (Nm) | Stucture Capacity lb (N) | Max Stroke Length (mm) | Specifications (PDF datasheets) |

|---|---|---|---|---|

| C–160D–173–86 | 160,000 (18,078) | 17,300 (76,954) | 86 (2,184) | View / Download (PDF) |

| C–228D–213–120 | 228,000(25,761) | 21,300(94,767) | 120(3,048) | View / Download (PDF) |

| C–320D–256–120 | 320,000(36,155) | 25,600(113,874) | 120(3,048) | View / Download (PDF) |

| C–456D–365–144 | 456,000(51,521) | 36,500(162,359) | 144(3658) | View / Download (PDF) |

| C–640D–305–168 | 640,000(72,310) | 30,500(135,671) | 168(4,267) | View / Download (PDF) |

SRP Automation & Control System

An Oil Pumping Unit Automation System designed to automate, monitor, and protect Sucker Rod Pump (SRP) units, replacing manual operation with intelligent control for efficient and reliable oil production.

Key Features

- Intelligent VFD (Variable Frequency Drive)

- SCADA-ready remote monitoring

- Real-time dynacard analysis

- Remote start / stop & speed control

Benefits

- Improved energy efficiency

- Reduced downtime and failures

- Lower maintenance costs

- Extended motor, rod & pump life

Customization & Support

- Custom stroke lengths and gearbox ratios

- Motor and drive configuration options

- Field installation, alignment, and commissioning

- Preventive maintenance kits and AMC contracts

Backed by 30+ years of engineering experience.

Need Help Choosing a Model?

Our engineering team can guide you based on load, well depth, and operating conditions.

Request a Quote Contact Us